MUSIC Lab at SUSTech

Home | People-Openings | Teaching | Research-Publications | Outreach | Facilities | Resources

News

» [10 Apr 2019] » Dr. Xiaomeng Gao receives the Best Young Professional Paper Award at WAMICON2019

» [01 Feb 2019] » DART Lab to Advance to Phase 3 of the DARPA SPAR Program

» [23 May 2018] » Songjie Defended his PhD Degree

» [20 Jan 2018] » DART Lab to Advance to Phase 2 of the DARPA SPAR Program

» [07 Mar 2017] » DART Lab Awarded NSF STTR Phase II Project on Developing a Radar-based Wearable Heart Health Monitoring Device

» [08 Nov 2016] » DART Lab to Participate in DARPA SPAR program

Due to its low insertion loss, high isolation, high linearity, wide bandwidth, and near-zero dc power consumption, radio frequency micro-electromechanical (RF-MEMS) switches have been an emerging technology with significant potential in many high frequency circuits and systems, especially those requiring reconfiguration. Compared to other high frequency switching technologies, metal contact RF-MEMS switches have the highest figure of merit (FoM, defined as 1/RonCoff) because of its ultimately low contact resistance and off-state capacitance. In addition, metal contact RF-MEMS switches have extremely large bandwidth that can extend from dc to beyond 100 GHz.

However, the reliability issues associated with RF-MEMS contact switches have been a major barrier for the wider adoption of the technology. Significant efforts have been devoted to improving the lifetime (primarily in terms of cycling time) of RF-MEMS contact switches. For example, the Radant MEMS switch can be cycled up to 100 billion times under cold-switching conditions. Under hot-switching conditions, however, the reliability of these switches degrades quickly with a sharp increase in contact resistance and insertion loss after a few tens of thousands of cycles. For applications where hot switching is needed, improving the reliability of RF-MEMS switches has been a significant challenge.

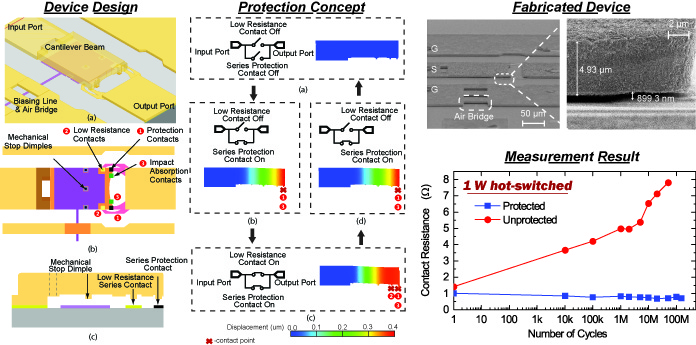

Our group has recently demonstrated an RF-MEMS switch design that can significantly extend the hot-switching life-time of RF-MEMS contact switches. The design concept is shown in the figure above. To prevent the contact degradation during in hot-switching events, a pair of series protection contacts are added in parallel with the "real" contacts. When the switch closes, the protection contacts close first and creates a low-voltage, near cold-switching condition for the "real" contacts. Although protection switches have been proposed in the past, this work combines the protection and "real" contact actuation into a single mechanical structure, and demonstrated unequivocally the significant improvement in hot-switching life-time. For unpackaged devices using Au-Au as the "real" contact material and Pt-Au as the protection contact material, we have demonstrated 150-million actuation cycles at 1-W hot-switching power and 50-million at 2 W. This is much better than anything we have seen!

This design concept can in fact be extended to a few more switch design variations which we are currently investigating. We have also been working on improving the contact materials and packaging for further switch life-time enhancement.

-

Yuhao Liu, Jiansong Liu, Bo Yu, and Xiaoguang Liu, "A Compact Single-Cantilever Multicontact RF-MEMS Switch With Enhanced Reliability," IEEE Microwave and Wireless Components Letters, vol. 28, no. 3, pp. 191-193, Mar, 2018. DOI:10.1109/LMWC.2018.2800523 |

-

Yuhao Liu, Yusha Bey, Xiaoguang Liu, "High-Power High-Isolation RF-MEMS Switches with Enhanced Hot-switching Reliability Using A Shunt Protection Technique," IEEE Transactions on Microwave Theory and Techniques, vol. 65, no. 9, pp. 3188-3199, Apr, 2017. DOI:10.1109/TMTT.2017.2687427 |

-

Yuhao Liu, Yusha Bey, and Xiaoguang Liu, "Extension of the Hot-Switching Reliability of RF-MEMS Switches Using A Series Contact Protection Technique," IEEE Transactions on Microwave Theory and Techniques Applications, vol. 64, no. 10, pp. 3151 - 3162, Oct, 2016. DOI:10.1109/TMTT.2016.2598170 |

-

[Invited]

Yuhao Liu, Hao Wang, Yusha Bey, and Xiaoguang Liu, "A Novel RF-MEMS Shunt Capacitive Switch Design for Dielectric Charging Mitigation," , vol. , no. , pp. , Jul, 2015. DOI:10.1109/IMWS-AMP.2015.7324955 |

-

Yuhao Liu, Yusha Bey, and Xiaoguang Liu, "Single-Actuator Shunt-Series RF-MEMS Switch," , vol. , no. , pp. , Jun, 2014. DOI:10.1109/MWSYM.2014.6848666 |